Topic last reviewed: November 2022

Sectors: Downstream, Upstream

Open-cycle gas turbines (OCGTs) are the simplest application of gas combustion for power/electricity generation. OCGTs consist of a gas turbine only and do not recover any waste heat. Therefore, the power system is less efficient than technologies that utilize waste heat for heating or extra power production; for further detail, please see the Combined Heat and Power Info Sheet and the Combined-Cycle Gas Turbines Info Sheet. Since OCGTs are less efficient, more fuel is required per unit power output. Without heat recovery, supplementary heating may also be needed from gas-fired heaters. Using OCGTs generally increases greenhouse gas (GHG) emissions; it is therefore important to consider other ways to generate power in order to improve efficiency and reduce GHG emissions.

The efficiency of an OCGT will vary with size and type of turbine selected. but tends to increase with size of the turbine. An onshore combined-cycle turbine efficiency is up to 60%, and offshore approximately 50% (although efficiency drops significantly at partial load). The high efficiency means that less fuel is consumed compared with other options, and this gas could be sold or utilized for other purposes.

OCGTs are currently found in many locations where gas is cost effective, but have been increasingly replaced by more efficient systems for new projects, e.g., CCGTs, combined heat and power (CHP), etc. OCGTs are still favoured for some niche applications (small, remote, variable and intermittent power, offshore, and peaking).

Applications for OCGTs in the oil and gas industry include pipeline natural gas compression/boosting stations, where little/no heat is required and location constrains the size and complexity of the equipment. Turbines up to about 70 MW may be either industrial or modified aeroderivative engines, while larger units up to about 330 MW are designed for specific purposes. For electric power applications, such as large industrial facilities, OCGTs can be utilized to provide peaking power in capacity constrained areas. Power utilities often use gas turbines in the 5–40 MW size range to provide incremental capacity and grid support. A significant number of OCGTbased CHP systems are in operation in a variety of applications, including oil recovery, chemicals, paper production, food processing, and universities.

Typical carbon dioxide (CO2) emissions from an aeroderivative 21 MW gas turbine without heat recovery and operating at around 30% efficiency are approximately 500 kg CO2/MWh. Such turbines have been heavily used offshore.

Technology description

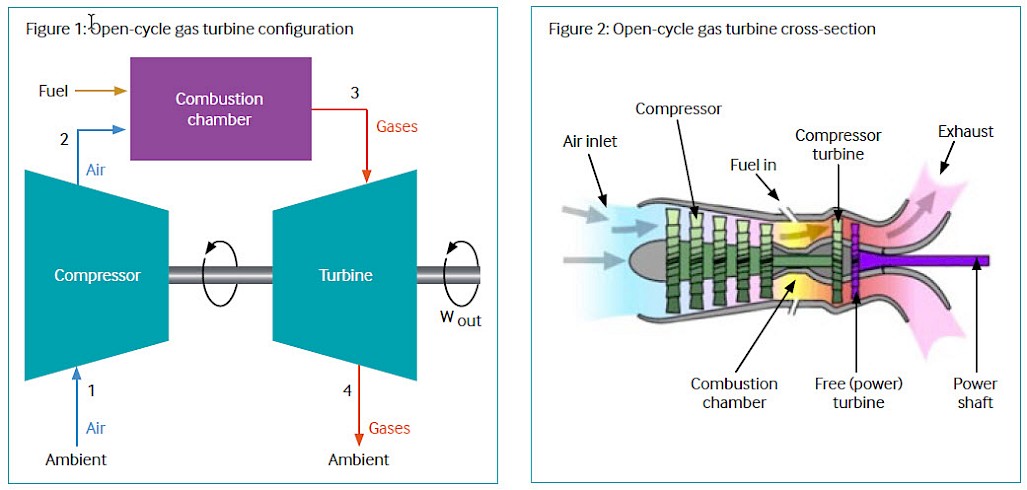

A gas turbine is an internal combustion engine that operates with rotary rather than reciprocating motion. Gas turbines are composed of three main components: compressor, combustor, and turbine. In the compressor section, air is drawn in and compressed up to 40 times ambient pressure and directed to the combustor section, where fuel is introduced, ignited, and burned.

The compressor, combustor, and turbine are connected by one or more shafts and are collectively called the gas generator or gas turbine. Figures 1 and 2 respectively illustrate a typical gas turbine generator configuration and schema.

Fuels

A variety of fuels can be used. Natural gas is preferred for most plants but liquefied petroleum gas, refinery gas, gas oil, diesel, naphtha, and light crude may be used. Turbines can also be dual fuel, for example gas and diesel, to manage issues with fuel supply and start-up/ backup. Aeroderivative gas turbines have more specific fuel requirements. Turbines with dry low emission (DLE) technology are capable of achieving very low NOx-emissions down to single digit values. There are also examples of turbines operating on synthetic gas with a 20% hydrogen specified content, and all major gas turbine original equipment manufacturers are working to develop up to 100% hydrogen capable gas turbines with DLE systems. This work should consider all aspects (supply, safety, cost, etc.) to enable more use of hydrogen fuel, which will reduce GHG emissions. Efforts are also ongoing regarding burning ammonia as a hydrogen carrier.

Effect of temperature and pressure

There are external (ambient) and internal factors that can have a strong influence on OCGT performance. Pressure and temperature are the most important.

External pressure and temperature (ambient air)

Gas turbine power and thermal efficiency are usually rated at the International Organization for Standardization (ISO) conditions: 15°C/60°F, 60% relative humidity, and 101.3 kPa. Power and thermal efficiency are inversely related to ambient temperature and proportional to ambient pressure. Humidity has a minor effect on efficiency.

For most gas turbine models, the power output decreases as ambient temperature increases. One method of increasing power output (increasing efficiency and reducing emissions) is to introduce air inlet chilling to reduce the ambient air temperature entering the gas turbine. This is more beneficial in tropical than temperate climates.

Compression ratio and firing temperature

The discharge pressure of the compressor relative to ambient pressure is termed the compression ratio and is an important parameter that affects efficiency. For a given firing temperature, a higher compression ratio will yield better efficiency.

Turbine firing temperature is proportional to specific output power. There is an optimum adiabatic temperature ratio between the compressor and turbine that maximizes power output.

Combined, the OCGT compressor, turbine design, compression ratio, and ambient conditions have a strong influence on thermal efficiency.

Partial-load efficiency penalty

Gas turbines achieve peak efficiency at full load. Operation at partial load comes with a reduction in thermal efficiency. As such, the variability of the power requirements, ambient conditions, and maintenance/sparing requirements should be considered in the number, type, and size of turbines. The aim is to target full-load operation and optimum thermal efficiency.

For variable electrical loads from OCGTs, with a high diurnal and seasonal temperature range, more numerous and smaller turbines may be preferred. This way, the power demand can be more closely matched to the load profile by operating the correct number of turbines, thus achieving better efficiency. Conversely, for constant loads in consistent weather, fewer, larger turbines may achieve similar efficiency.

In the context of sparing, partial-load efficiency should also be considered when sizing turbines. For electrical systems, it is undesirable for a single gas turbine trip to cascade to system blackouts. As such, most islanded electrical systems/grids use a spinning reserve, meaning the system can use the spare capacity in the event of a gas turbine trip before the electrical system trips. At least one spare turbine is required to be operated above load. For example, for a 200 MW load, operating six 40 MW turbines produces a 240 MW capacity, which can cover the loss of a single OCGT. Spinning gas turbines is an operational inefficiency that consumes fuel, producing CO2. There are alternatives to a spinning reserve, including fast electrical load shedding and batteries.

Aeroderivative turbines usually have a better turndown throughout their load profile when compared with industrial types.

Improvements

Manufacturers continue to make improvements to gas turbines through the development of improved materials, combustion technology, and techniques. Other upgrades, such as inlet air cooling and, compressor intercoolers, can provide more power. This can improve or decrease overall efficiency, depending on the application and overall system.

Technology maturity

| Commercially available | Yes |

| Offshore viability | Yes |

| Brownfield retrofit | Yes |

| Years of experience in industry | >30 |

| Years of experience in oil and gas industry | >30 |

Key metrics

| Range of application | Turbines up to about 50 MW may be either industrial or modified aeroderivative engines, while larger units up to about 330 MW are designed for specific purposes. Smaller size turbines are typically used for offshore applications due to lower weight. |

| Efficiency | For modern aeroderivative gas turbine models, typically 33–43% at maximum load. This drops significantly at partial loads. Old gas turbines from the 1980s would be in the range of 25%. |

| Energy key performance indicators | Effective electrical efficiency, % loading, nitrogen oxides (NOx) emissions. |

| Guideline capital costs | Offshore greenfield, less expensive than combined- cycle. |

| Guideline operational costs | More fuel is used, increasing operational costs and increasing GHG emissions costs. Excluding fuel costs, generally cheaper to operate than CCGT or CHP. |

| Typical scope of work description | For new offshore installations, it is important to analyse the need for power and heat, sparing requirements, available space, and weight restrictions to design an optimal solution to balance capital costs, logistical constraints, and fuel and emissions costs. For existing offshore platforms with OCGT generators, the space and weight constraints of installing a waste heat recovery unit and steam turbine generator should be considered. Such modifications may be costly or technically infeasible for some offshore installations, and the capital cost for modification, operational cost savings from using less energy/fuel, and reduced GHG emissions should then be evaluated before the decision to retrofit the power system can be taken. |

Decision drivers

| Technical |

|

| Operational | Operators need to be trained for turbines only (no steam system training needed). |

| Commercial | Larger size turbines operate at higher efficiency but are not as efficient as the combined cycle system. Driven by fuel gas price and CO2 price versus incremental capital costs. |

| Environmental | Lower energy efficiency than CCGT or CHP. Lower OCGT efficiency means increased GHGs, NOx, carbon monoxide, volatile organic compounds, and particulate matter per produced MWh. |

Alternative technology

OCGTs are the simplest application of gas combustion for power/electricity generation and are less efficient than technologies that utilize waste heat for heating or extra power production. For more information, please see the Combined Heat and Power Info Sheet, the Combined-Cycle Gas Turbines Info Sheet, and the Organic Rankine Cycle Info Sheet. There are also compact heat recovery options available that can minimize deck space. Gas engines or diesel engines may also be alternatives to OCGTs, but diesel is expensive and has other disadvantages like NOx and sulphur oxides emissions.

Operational issues, risks and opportunities

With time in operation, gas turbine performance will decrease. Contaminants in the intake air will make the turbine dirtier and reduce efficiency. Oil and gas production on several installations is often limited by the available power from the gas turbines, and any deterioration in gas turbine performance directly affects production rates. Fouling in the compressor section of the gas turbine is the main contributor to this performance deterioration. Most of the degradation is recoverable and fouling can be removed by water washing the compressor section. An efficient water wash will reduce gas turbine deterioration, thus increasing the available power from the gas turbine, and the gas turbine efficiency will increase. Fouling and deterioration can also be reduced by changing the turbine inlet filters frequently. Both water washing or change of inlet filters will lead to lower fuel consumption and lower emissions of CO2 and NOx.

Normally, this water wash is done offline. Frequent intervals for offline water wash will increase the turbine efficiency, but this is also a time-consuming operation. The turbine’s inlet air filter pressure drop can be monitored, and filters can be changed to avoid deterioration. Online water wash or changing the inlet air filter are options that can be used to increase the efficiency. Experience from an operator is that changing the inlet filters is easier than an online water wash and increases the efficiency by the same amount. For an aeroderivative turbine of 21 MW used offshore, changing the inlet filter could increase efficiency by 0.4–0.8 MW, saving up to approximately 4000 tonnes of CO2 per annum.