Topic last reviewed: November 2022

Sectors: Upstream, Downstream

Utilizing waste heat from processes can reduce on-site energy consumption and associated emissions (see the Combined Heat and Power topic and the Pinch Analysis topic). However, in many cases the waste heat source’s temperature is not high enough to extract useful energy via conventional steam/water Rankine cycles.

The best known and most widely applied alternative thermodynamic cycle is the organic Rankine cycle (ORC). The principle of the ORC is based on a turbogenerator working like a conventional steam turbine to transform thermal energy into mechanical energy and finally into electrical energy through an electrical generator. Instead of generating steam from water, the ORC system vaporizes an organic fluid, characterized by a molecular mass higher than that of water and with a boiling point lower than that of water, allowing for capture of lower temperature heat for useful work.

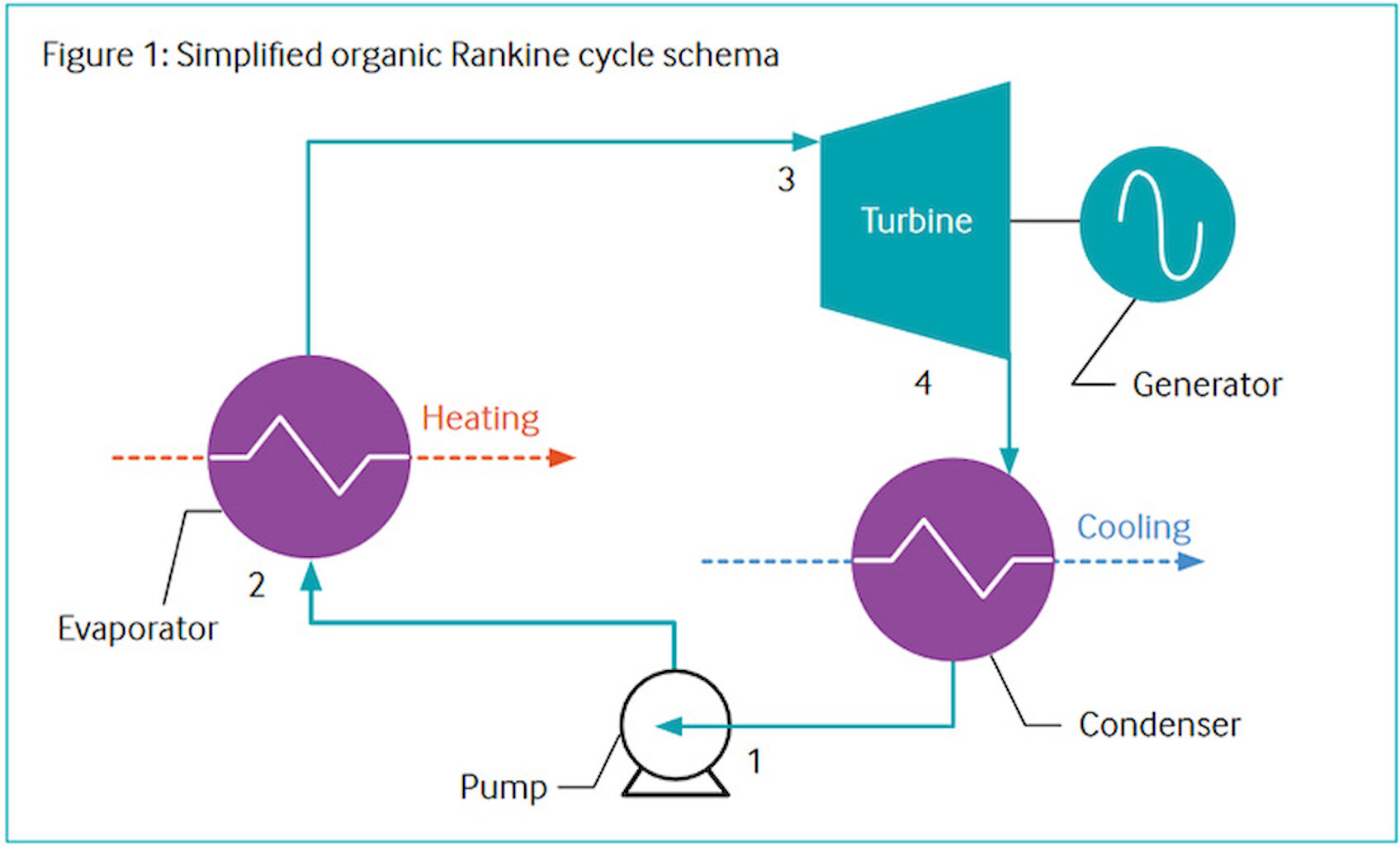

A simplified schema of an ORC is shown in Figure 1.

Heating in the evaporator (often known as the primary heat exchanger) might be by gas turbine waste heat recovery. Condenser cooling will usually be by cooling water or air.

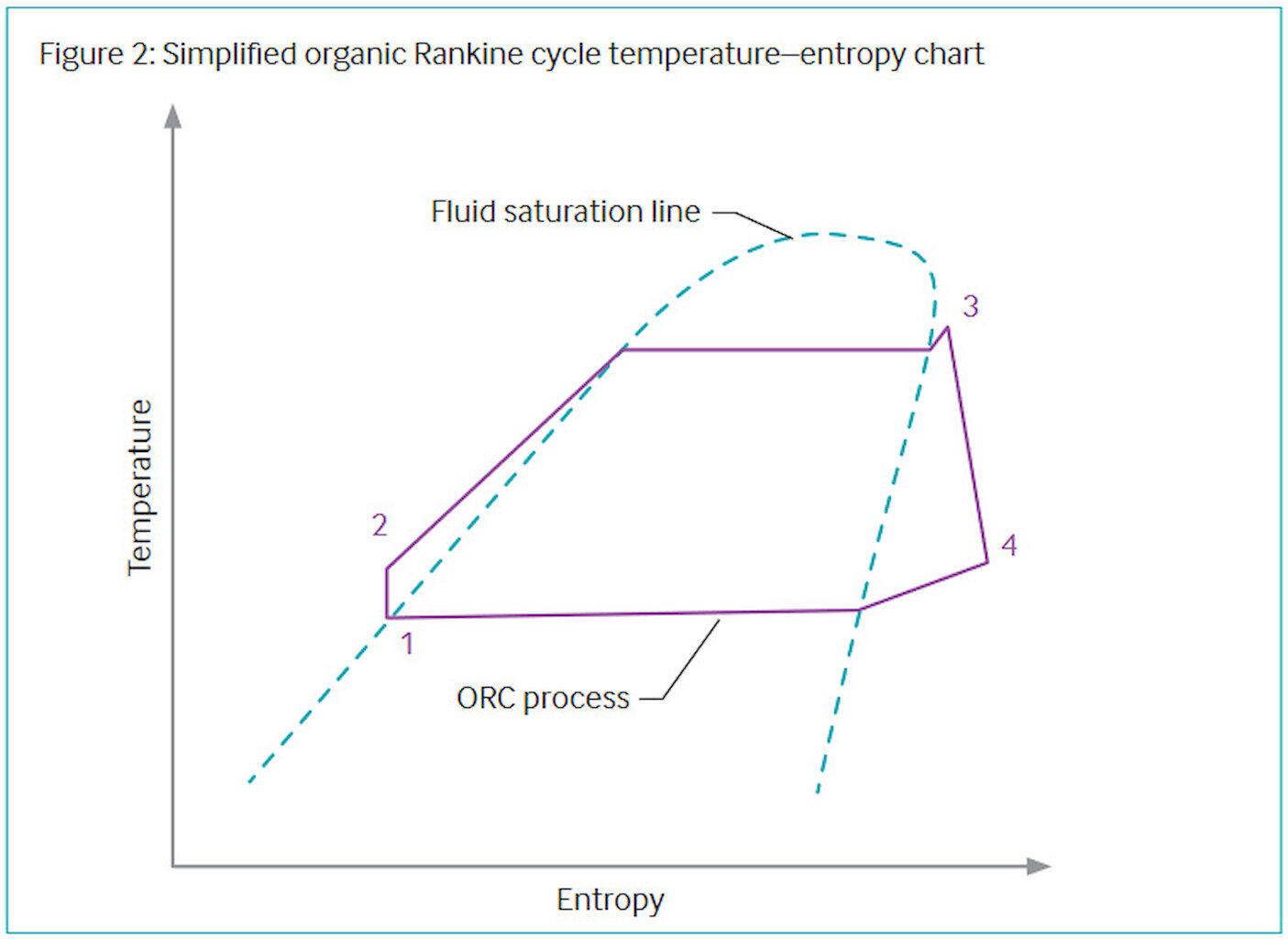

The corresponding temperature–entropy chart illustrating the thermodynamic cycle for this simplified system is shown in Figure 2. Further information on the ORC thermodynamic cycle may be found in Reference 1 and Reference 2.

The ORC can utilize process waste heat from numerous sources, such as heating systems, cooling systems, and power generation. Most ORC references in the oil and gas industry are related to power generation as the ORC can generate additional power from open-cycle gas turbines (OCGTs) without consuming additional fuel and without adding the expensive steam infrastructure required for steam-based combined-cycle gas turbine conversion. However, the ORC will generate less power than a steam cycle operating with similar conditions, and costs can be higher for specific applications. The working fluid used in an ORC cycle is combustible, and if leakages occur, process safety and environmental hazards will result.

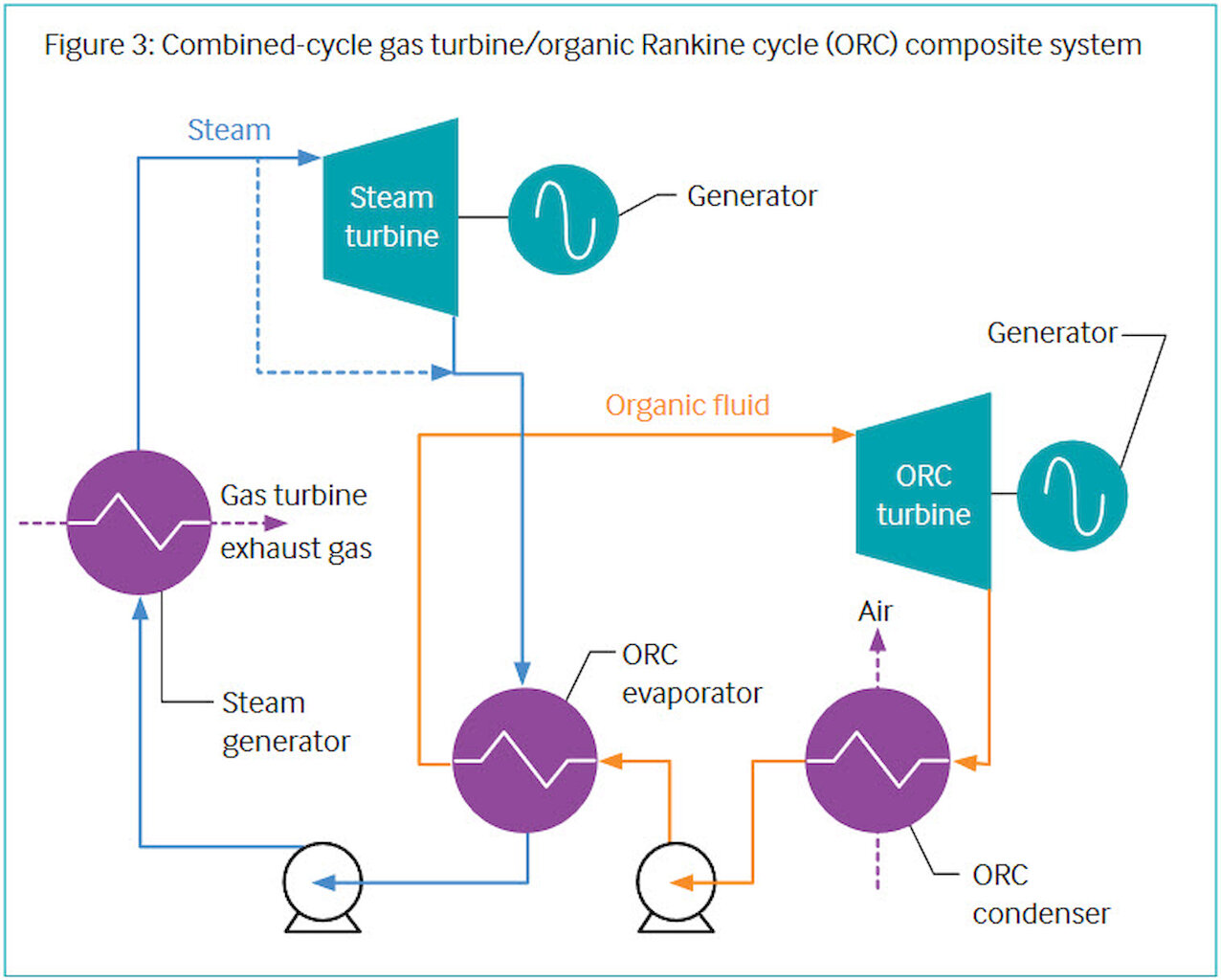

The ORC can be used in conjunction with a combined-cycle system as illustrated in Figure 3, in which the organic fluid acts as a condensing medium for the steam cycle.

Most ORC installations are based on a single pressure level arrangement; multi- pressure-level arrangements are possible but are rarely applied due to the additional complexity that would be introduced.

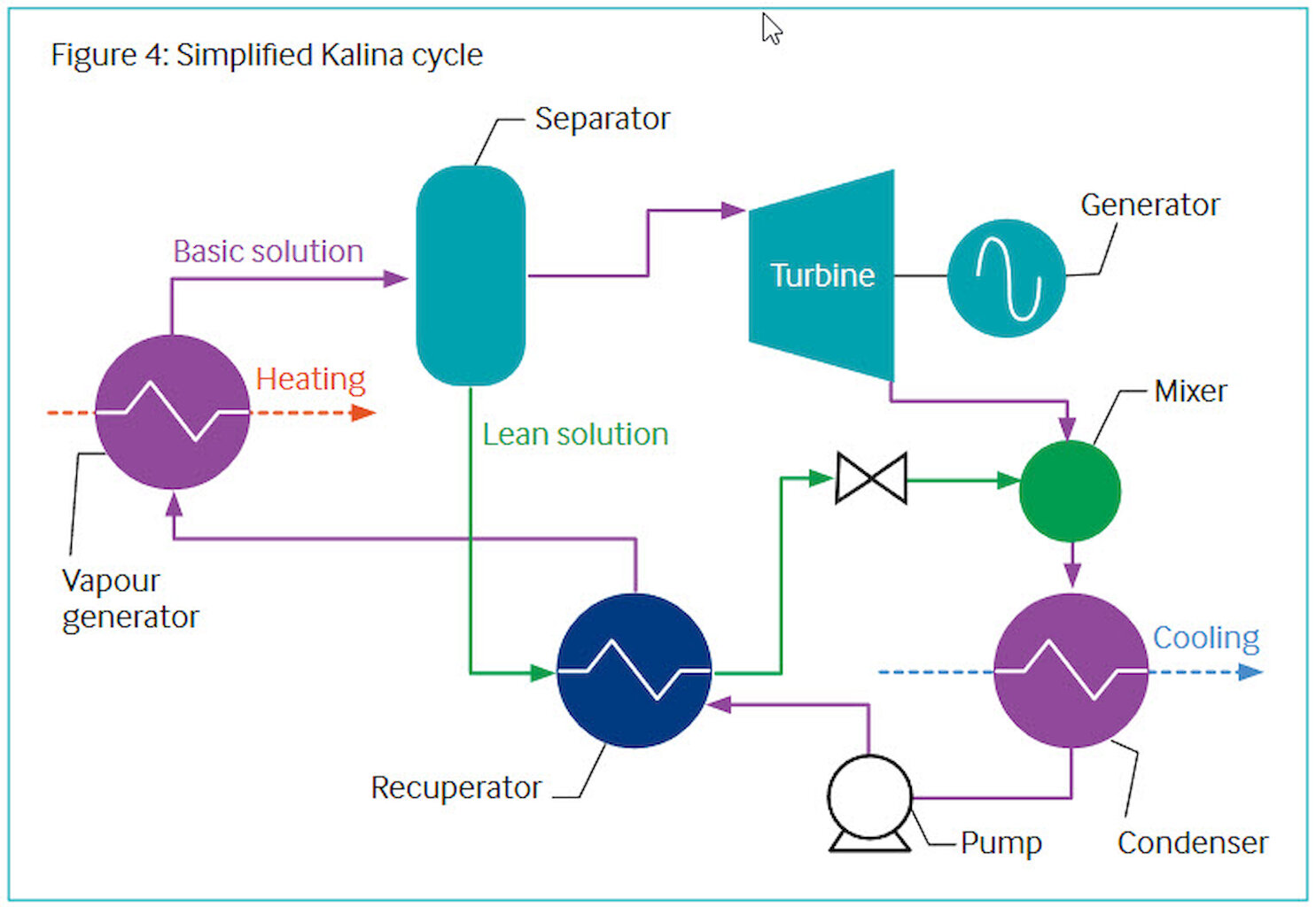

The Kalina cycle is a modified Rankine cycle which uses a working fluid of at least two components with different boiling points. An ammonia–water solution is often used. A simplified schema is provided in Figure 4.

The Kalina cycle has some thermodynamic advantages over the conventional Rankine cycle and the ORC and has attracted some interest from the cement and geothermal industries.

Technology maturity

| Commercially available | Yes |

| Offshore viability | Yes |

| Brownfield retrofit | Yes |

| Years of experience in industry | 30+ |

Years of experience in oil and gas

industry | 15+ |

Key metrics

| Range of application | The ORC can be used to utilize low grade heat from: - gas turbine exhausts

- heating or cooling systems

- produced fluids

|

| Efficiency | System dependent, typically in the range of 10–20% |

| Energy key performance indicators | - Additional energy recovered, kW

- System efficiency, %

- Utilization %

|

| Typical scope of work description | For new offshore installations, it is important to analyse the need for power and heat, sparing requirements, available space, and weight restrictions to design an optimal solution to balance capital costs, logistical constraints, and fuel and emissions costs For existing offshore platforms with open-cycle gas turbine generators, the space and weight constraints to install a waste heat recovery unit and ORC turbine generator should be considered. Such modifications may be costly or technically infeasible for some offshore installations, and an analysis of the capital cost for modification, operational cost savings from using less energy/fuel, and reduced greenhouse gas emissions should then be evaluated before the decision to retrofit the power system can be taken |

Decision drivers

| Technical | Space for addition of an ORC system |

| Operational | Additional equipment to operate and maintain. Introduction of an organic-hydrocarbon- based operating fluid |

| Commercial | Determining how much additional power could be utilized by addition of an ORC system |

| Environmental | Evaluate environmental risks associated with selected working fluid (e.g., fugitive emissions) |

Alternative technology

Supercritical carbon dioxide cycles may eventually be more attractive with lower cost and space but are not yet commercially available.

Operational issues/risks

Use of hydrocarbon-based operating fluid introduces risks associated with the potential loss of containment of a potentially hazardous fluid that should be mitigated.

Opportunities/business case

Utilization of waste heat from open cycle gas turbine systems to generate additional power, or equally can reduce fuel input for the same power demand. Upstream facilities across the globe have a significant number of open cycle gas turbine systems with 25–40% fuel-to- power efficiency.

References

- Macchi E and Astolfi M. Organic Rankine Cycle (ORC) Power Systems – Technologies and Applications. Duxford, UK: Woodhead Publishing, 2017.

- Colonna P, et al. “Organic Rankine cycle power systems: from the concept to current technology, applications, and an outlook to the future.” Journal of Engineering for Gas Turbines and Power, ASME Digital Collection, 137:10. 100801. 2015.