Topic last reviewed: 10 April 2013

Sectors: Downstream, Upstream

Nuclear energy generation is based on the principle of fission (‘splitting’) of nuclei of heavy elements, such as U-235 (uranium 235 — an isotope of uranium), to release the energy which holds each nucleus together. The life-cycle GHG emissions per unit of electricity from nuclear power plants are at least two orders of magnitude lower than those from fossil fuelled electricity generation, and are comparable to most renewables at near zero (Reference 12). One obstacle to the deployment of nuclear energy plants is the licensing process which can be lengthy and costly (Reference 13). Given the safety concerns relating to nuclear technology, there could be significant upfront costs involved in building a demonstration reactor and conducting the studies required to demonstrate the safety of this technology.

There are a variety of reactor concepts, as summarized below. Each contains a nuclear reaction system, a heat removal system, and a multitude of safety systems to prevent release of the highly radioactive material generated in the fission process. The heat removal system can be used to generate steam. The most common commercial nuclear reactors are thermal reactors, in which the neutrons released by fission are slowed down by passing them through a relatively light material known as a ‘moderator’, such as water (H2O), deuterium or carbon.

Light water reactors (LWRs)

These are the most common commercial nuclear reactors (Reference 1), and utilize water as the neutron moderator as well as for the coolant. In an LWR, the nuclear reaction system consists of UO2 (uranium dioxide) pellets with 2–4% U-235 contained in zircoloy cans which are bundled into fuel assemblies, with water used as both the neutron moderator needed to maintain the nuclear chain reaction and as the coolant to remove the heat, thereby producing steam to generate power. There are two variations of LWRs:

- The boiling water reactor (BWR), where the water that serves as the moderator and coolant is also converted to steam in the reactor core and used to run the turbine.

- The pressurized water reactor (PWR), where water that serves as the moderator and coolant is superheated in the reactor core, under about 2200 psia pressure, and then passed through a steam generator to produce a secondary flow of steam used to run a turbine. PWRs are the most prevalent LWR design in use.

Most installed LWRs are generation II (Gen II) with active safety systems, pumps and valves that need power to actuate. Using the lessons learned from the Three Mile Island accident in 1979, passive safety systems, where water is inserted by gravity, have been designed to reduce the need for pumps and to streamline the safety systems. These are called Gen III reactors. Typically, Gen II or Gen III reactors are rated at 1000 MWe with 33%–35% efficiency.

High temperature gas reactors (HTGRs)

Outlet temperatures of LWRs, under normal operating conditions, would not be sufficiently high for use in traditional steam and process heat operations in upstream oil and gas, such as steam flooding of heavy oil reservoirs, steam-assisted gravity drainage (SAGD) of oil sands, or for producing hydrogen needed for various downstream applications. Consequently there has, until recently, been a significant interest in high temperature gas reactors (HTGRs), where helium is used as the coolant. There are two competing designs for this type of reactor (Reference 13):

- Spherical tennis ball-sized fuel elements loaded into a graphite silo. In this design, the fuel contained in graphite-based pebbles are in a bed, free to flow for dynamic refuelling,

- Hexagonal fuel elements, with fuel loaded into precisely located graphite hexagonal prisms. In this configuration, the fuel is in a prismatic assembly form that is closer to conventional fixed fuel design, and thus refuelling would be periodic.

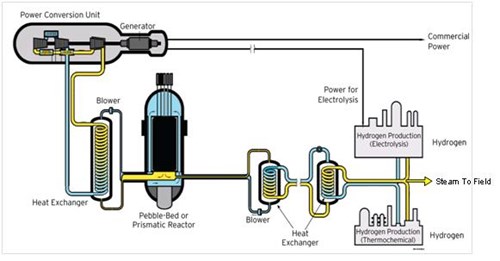

HTGRs can be used to produce steam and process heat for high temperature applications in addition to producing electricity (References 2–5). The US government's interest was codified in the 2005 U.S. Energy Act, with a special focus on hydrogen generation. One of the above designs was to be used for the Next Generation Nuclear Plant (NGNP), which was funded for R&D under the USDOE 2005 and 2007 Energy Acts. Several competing groups had assembled to propose competing designs to the Nuclear Regulatory Commission (NRC) for licensing. Most currently planned HTGRs are being designed for a rating of approximately 200 MWe with 40% efficiency. HTGRs are viewed as Gen IV nuclear technology. Figure 2 illustrates the schematic of an HTGR.

Figure 2: High temperature He-cooled reactor for electricity and process heat

(Adopted from Badruzzaman et al., SPE Paper 119264, 2008; the original figure was Courtesy of Idaho National Lab.)

With the 2008 economic crisis, interest in HTGRs decreased. The South African Company, PBMR Pty, whose pebble concept was leading much of the effort, went out of business. The USDOE’s interest in the NGNP also waned as Small Modular Reactors (SMNRs, discussed below) gained favour. The USDOE now expects the NGNP project to be an R&D project where utilities, rather than the government, would apply for a licence to build and operate the plant. Thus, in order to promote HTGRs, an NGNP Industry Alliance was formed in 2010–2011. It was anticipated that the Alliance would receive government support, but that remains unresolved. The Alliance has gone ahead and selected a preferred design, lead by the French nuclear reactor company Areva (Reference 14). Their design is for a 625 MWth prismatic reactor, which would cogenerate electricity and 566°C process steam. The reactor would likely be sited at an existing nuclear plant site close to a chemical complex that needs process steam, instead of constructing a new site in the USDOE complex at Idaho National Lab.

China is also building a helium-cooled HTGR plant, possibly the world’s first commercial HTGR plant of its kind.

Canada deuterium uranium reactor (CANDU)

Another reactor type that has gained popularity is the CANDU reactor that uses heavy water (deuterium oxide) as the moderator, which allows for use of natural, un-enriched uranium as the fuel source, thereby saving on enrichment costs. Similar to the PWR, this design isolates the coolant from the turbine driver. All reactors built in Canada are of the CANDU type, and the technology has also been utilized in several other countries.

Small modular nuclear reactors (SMNRs)

The power rating of small modular nuclear reactors (SMNRs) can generally range from 50 KWe to 325 MWe per module. One concept of SMNRs falls under the category of integral pressurized water reactors (iPWRs). These are small versions of proven PWRs, for example, the 125 MWe module mPower developed by Babcock & Wilcox (B&W) and 50 MWe module developed by Nuscale. Westinghouse has developed an SMNR based on its successful PWR design. USDOE funding for these would be under Licensing Support. Other proposed SMNRs such as the Hyperion module, EM2 (by General Atomics), or the Travelling Wave Reactor are commercially unproven. Most of these designs are based on so-called fast reactor concepts which produce plutonium that is consumed in situ to produce power. Some SMNRs are being designed as nuclear batteries where reactors will be factory assembled and sealed for a 15–20 year life requiring minimal intervention. USDOE funding for SMR advanced concepts R&D has gone from approximately $3.1 million in 2011 to over $28 million in 2012. Most SMNRs are planned to be situated underground thereby avoiding the need for surface containment systems as used in conventional reactors to contain the release of radioactivity to the environment in case of an accident. However, building plants underground could add to the cost of the plant and face regulatory hurdles, dealing with issues such as water table contamination or earthquakes. See the References 6–10 for more details on SMNRs.

Technology maturity

| Commercially available?: | Yes |

| Offshore viability: | No |

| Brownfield retrofit?: | No |

| Years experience in the industry: | <5 |

Additional notes

NB: Additional detail on the above technology maturity information is provided below.

- Commercially available: Yes (Gen III, CANDU); No (HTGR, SMNR)

- Industry segments: Upstream potential: HTGR, CANDU, PWR for thermal EOR (e.g. steam flooding, SAGD (see Reference 14)); subsea (SMNR)

LNG (HTGR and/or SMNR)

Downstream: HTGR for H2 production, cogeneration

- Offshore: No (future potential for subsea use)

- Brownfield retrofit: Possible

- Years of experience in the industry: No known commercial experience in the oil and gas industry. In the power industry: 40+ years

Key metrics

Range of application: | ~150 kW – 1000 MWth, in either power only or cogeneration mode |

| Efficiency: | 35–40% (power), higher if cogen |

| Guideline capital costs: | Greenfield: See case study below and Reference 14 for more details |

| Guideline operational costs: | Data not available |

| Typical scope of work description: | Economic analysis and continued technology assessment |

Decision drivers

| Technical: | Footprint: plot area required/safety zone: HTGR ~ 400-metre radius vs. 10-mile radius for LWRs Waste handling: Unresolved HTGR/SMNR: Yet to be proven for commercial application. USDOE plans are evolving — First Of A Kind plants likely to be in partnership with industry |

| Operational: | Cooling redundancy, highly trained operators, licensing issues, security, safety Maximum temperature (HTGRs): 700-900 °C |

| Commercial: | Yes (Gen III, but not for oil and gas operations). No (HTGR and SMNR) Economic rule of thumb: $6–7/mcf natural gas price to breakeven, but can vary from region to region, country to country (Reference 4) There are significant costs involved with licensing the technology, building a demonstration reactor, and performing studies required to demonstrate the safety of the technology. |

| Environmental: | Significant reduction in air and greenhouse gas (GHG) emissions Waste disposal issues are unresolved |

Alternative technologies

The following are technologies that provide similar benefits and may be considered as alternatives to combined nuclear heat and power:

- Steam generators/boilers: Increased gas reserves and shale gas production have had an impact on the level of interest in HTGRs for steam and process heat. The Fukushima incident involving LWRs located in a seismically active region has increased the demand for natural gas for electricity generation. Abundant and inexpensive shale gas in the USA has altered the prospects for nuclear energy for both electricity and process heat/steam generation.

- Natural gas fired combined cycle cogeneration systems (including IC engine generator sets, turbines, fuel cells, and larger gas turbine-steam turbine systems)

Operational issues/risks

HTGRs

Operational issues: Dynamic refuelling for pebble bed fuel vs. scheduled refuelling of prismatic fuel; helium coolant supply; expert personnel due to novelty of the design.

Risks: Failure of safety systems. Since fuel would not melt (but could crack in extreme conditions), impact would be easier to manage than for LWRs.

SMNRs:

Operational issues: An LWR-based SMNR would have similar operational issues to those of LWRs.

Risks: Safety risks would be similar to those of LWRs, but by being located underground, the release of radioactivity would likely be small. Some SMNRs face financial viability risks (see Reference 11, on NusCale Power).

LWRs:

Operational issues: Refuelling at regular intervals, operational safety, fuel availability, expert personnel.

Risks: Failure of cooling systems, core meltdown and failure of containment system to prevent release of radioactivity; Gen III passive safety system makes the design much safer than Gen II reactors and allows a longer lead time to implement emergency measures.

Opportunities/business case

Integration of nuclear power with in-situ oil extraction — assessment

(Reference 13)

An analysis was performed to evaluate the technical and economic aspects of utilizing nuclear energy to meet the energy needs of a Canadian oil sands extraction facility using SAGD technology. Three scenarios for the use of the nuclear reactor were analysed:

- Using the reactor to produce only the steam needed for the SAGD process

- Using the reactor to produce steam as well as electricity for the oil sands facility

- Using the reactor to produce steam, electricity, and hydrogen for upgrading the bitumen from the oil sands to syncrude

Additionally, three types of nuclear reactors were studied. The report showed that nuclear energy could be feasible, practical, and economical for use at an oil sands facility, depending on market natural gas prices, CO2 constraints/charges and environmental permitting issues.

Baseline scenario

Natural gas combustion to meet energy needs for recovery, extraction, upgrading and other site operations.

Energy efficiency project activity

Three cases were analysed:

- Reactor produces only the steam needed for the SAGD (production of bitumen)

- Reactor produces steam as well as electricity for the oil sands facility

- Reactor produces steam, electricity, and hydrogen for upgrading the bitumen

Nuclear reactors considered

- Canadian ACR-700 (CANDU) — 2,034 MWth/703 MW electricity (MWe) capacity

- Westinghouse’s AP 600 (PWR) — 1,933 MWth/610 MWe capacity

- Pebble Bed Modular Reactor (PBMR) — 400 MWth/165 MWe capacity

Estimated costs

Following is a comparison of the total cost (US$, 2005 cost basis) over the 30-year lifetime of a plant with a 100,000 bbl/day bitumen processing capability. For each case, the total cost includes capital, operating and maintenance, fuel and decommissioning costs. For any given case, the table below compares the different options on an equivalent energy and electricity needs basis. Costs for natural gas steam generation are based on a reference cost for natural gas price of $8/MMBtu.

| Energy efficiency case | Natural gas steam generation (baseline) $MM | CANDU (ACR-700) technology, $MM | PWR (AP-600) technology, $MM | PBMR technology, $MM |

| Case 1: reactor used only for steam production | $6,774.1 | $5,068.9 | $5,016 | $4,627.1 |

| Case 2: reactor used for steam and electricity production | $6,899.5 | $4,515.7 | $4407.5 | $3,929.8 |

| Case 3: reactor used for steam, electricity, and hydrogen production | $6,075.6 | $3,853.6 | $3,646.7 | $2,817 |

Costs on a comparable basis per unit of steam or hydrogen produced are shown in the table below:

| Natural gas | CANDU (ACR-700) | PWR (AP-600) | PBMR | ||

| Process heat + electricity (total cost per unit steam, $/m3) | Make electricity | 9.32 | 3.97 | 3.73 | 2.66 |

| Buy electricity | 9.04 | 5.22 | 5.10 | 4.22 | |

| Hydrogen (total cost per unit bitumen, $/bbl) | Make hydrogen | 1.75 | 1.90 | 1.81 | 1.64 |

Cost savings

- Nuclear energy costs can range from 2 to 3 times less than the costs of similar natural gas energy (based on $8/MMBtu gas price), but savings are highly dependent on natural gas prices.

Energy savings and emission reductions

- Nuclear option (compared to natural gas) avoids the release of 100 megatonnes of CO2 per year (for a 100,000 barrel per day bitumen or syncrude plant).

References:

- US NRC (website): ‘Light Water Reactor’

- Badruzzaman, A., Hedges, J., Demayo, T. and Sigworth, H. (2008). ‘Nuclear Energy for Unconventional Fossil-fuel Resource Recovery’. Document ID 119264. In Proc. SPE Annual Technical Conference and Exhibition, Denver, Colorado, 21–24 September 2008.

- Idaho National Laboratory Reports, 2009–2010.

- Bersak, A. and Kadak, A. C. (2007). ‘Integration of Nuclear Energy with Oil Sands Projects for Reduced Greenhouse Gas Emissions and Natural Gas Consumption’. Department of Nuclear Science and Engineering, MIT, Cambridge MA.

- Southworth, F.H., et al. (2003). ‘The Next Generation Nuclear Plant (NGNP) Project’. Idaho National Engineering and Environmental Laboratory. Doc. ref. INEEL/CON-03-01150.

- B&W (website): ‘Modular Nuclear Reactors’ (information of the B&W mPower reactor)

- Peterson, Otis G. (2008). Patent Application No. 11/804,450: Self-regulating nuclear power module, 20 March 2008. Describes the concepts applicable to [Hyperion] SMNRs.

- General Atomics (website): ‘Energy Multiplier Module (EM2)’

- van Dam, H. (2000). ‘The Self-stabilizing Criticality Wave Reactor’. Proc. of the Tenth International Conference on Emerging Nuclear Energy Systems (ICENES 2000), p.188, NRG, Petten, Netherlands.

- The New York Times (2009). ‘Science Illustrated: A New Scale for Nuclear Power’. Feature on the NuScale reactor, 1 December 2009

- Rogoway, Mike (2011). ‘NuScale Power, still seeking rescue, will lay off most employees tomorrow’. In The Oregonian, 17 March 2011.

- Sims, Ralph E.H., Rogner, H. and Gregory, K. (2003). Carbon emission and mitigation cost comparisons between fossil fuel, nuclear and renewable energy resources for electricity generation. In ‘Energy Policy’ 31 (2003), pp.1315–1326.

- Finan, A.E., Miu, K. and Kadak, A.C. (2005). ‘Nuclear Technology & Canadian Oil Sands: Integration of Nuclear Power with In-Situ Oil Extraction’. MIT, Department of Nuclear Science and Engineering, Cambridge MA.

- Nuclear Power Expert Panel (2009). ‘Report on Nuclear Power and Alberta’. A report prepared for the Minister of Energy.

- World Nuclear News (website): ‘Areva modular reactor selected for NGNP development’. 15 February 2012.